Ohio Work Permits for Minors⁚ A Comprehensive Guide

This guide provides comprehensive information about Ohio work permits for minors, covering eligibility requirements, application procedures, important regulations, and relevant resources. It aims to empower young workers and their families with the knowledge necessary to navigate the process effectively.

Introduction

In Ohio, obtaining a work permit is a legal requirement for minors under the age of 18 who wish to engage in paid employment. These permits serve as a crucial safeguard, ensuring that young workers are protected from exploitative labor practices and granted the opportunity to balance their work commitments with their educational pursuits. The Ohio Department of Commerce, through its Division of Industrial Compliance and Labor, oversees the issuance of these permits, emphasizing the state’s commitment to the well-being of its young workforce.

Eligibility Requirements for Ohio Work Permits

To be eligible for an Ohio work permit, minors must meet specific criteria. They must be at least 14 years old and enrolled in school. If they are 16 or 17 years old, they can work during the school year without needing a work permit under House Bill 1002, but they still need a permit during the summer months. Minors must also obtain parental or guardian consent, and employers are required to provide a statement confirming the nature of the work and the hours of employment. These requirements aim to ensure that minors are working in safe and appropriate environments.

How to Obtain an Ohio Work Permit

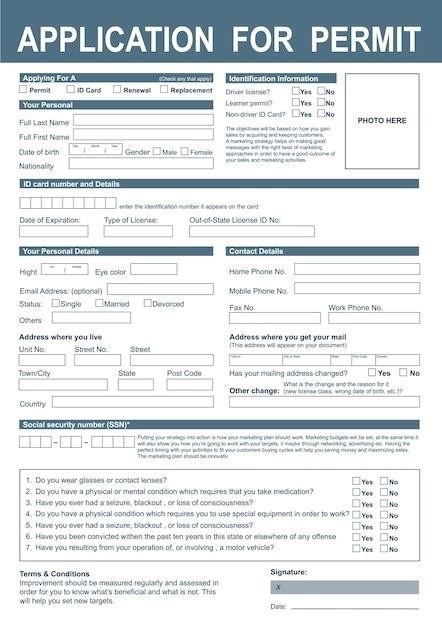

The process of obtaining an Ohio work permit involves several steps. First, download and complete the Application for Minor Work Permit form. This form requires information from the student, their parent or guardian, and their employer. Once completed, secure employer approval by having the employer sign the designated section of the form. Next, obtain parental or guardian consent by having them sign the form. Finally, submit the completed application to your school, along with proof of age, such as a birth certificate or school ID. The school will then process the application online, and the student will be issued an official work permit that must be signed by them.

Step 1⁚ Download and Complete the Application

The first step in obtaining an Ohio work permit is to download and complete the Application for Minor Work Permit form. This form can be found online at the Ohio Department of Commerce website. The form requires information from the student, their parent or guardian, and their employer. The student will need to provide their name, address, date of birth, and school information. The parent or guardian will need to sign the form to consent to the student’s employment. The employer will need to provide their name, address, and business information, as well as a description of the job the student will be performing.

Step 2⁚ Secure Employer Approval

Once the student has completed their portion of the application, they must obtain their employer’s approval. This involves the employer reviewing and signing the Employer Information section of the application. The employer must confirm that the student meets the age requirements for the job, that they will be paid at least minimum wage, and that they will not be working more than the legally allowed hours. The employer must also pledge to comply with all applicable Ohio and federal laws relating to the employment of minors.

Step 3⁚ Obtain Parental/Guardian Consent

Parental or guardian consent is a crucial step in the work permit process. The student’s parent or legal guardian must review the application, ensuring they understand the job details, working hours, and any potential risks. They must then sign the Parental/Guardian Consent section of the application, indicating their approval for the minor’s employment. This step emphasizes parental involvement and ensures that the minor’s well-being and safety are prioritized.

Step 4⁚ Submit the Completed Application to Your School

Once the application is fully completed, including parental consent and employer approval, the student must submit it to their school’s main office. If the student is homeschooled or attends an alternative education setting, the application should be submitted to the school district where they reside; The school office will then process the application electronically through the Ohio Bureau of Wage & Hour website. The student will need to personally sign the final work permit in the presence of a designated school official.

Important Information Regarding Ohio Work Permits

Ohio work permits for minors are crucial for ensuring compliance with labor laws and protecting young workers. Understanding the rules and regulations surrounding these permits is essential. For instance, minors aged 16 or 17 are exempt from work permit requirements during summer vacation. Furthermore, it’s important to note that work permits are not required for individuals over 18 years old, even if they are still attending school. These permits are generally valid for one year from the date of issuance and must remain on file at the minor’s workplace.

Work Permit Validity

Ohio work permits for minors are typically valid for one year from the date of issuance. This means that a minor who obtains a work permit in January 2024 will need to reapply for a new permit in January 2025 to continue working legally. It is essential to remember that a minor cannot legally work without a valid work permit. This ensures that the minor is not working in a prohibited job or exceeding legal work hours.

Exemptions from Work Permit Requirements

While most minors in Ohio need a work permit to legally work, there are some exemptions. Minors aged 16 or 17 who are working during the summer vacation months are not required to have a work permit. Additionally, minors who have graduated from high school, regardless of their age, are not required to obtain a work permit. Furthermore, minors who are enrolled in and attending a career and technical education program are not required to obtain a work permit.

Work Permit Regulations for Summer Employment

Ohio has specific regulations for minors working during the summer months. Minors aged 16 or 17 are exempt from the work permit requirement during the summer vacation period. However, minors under the age of 16 still need a work permit, even during the summer. Employers must retain a copy of the minor’s proof of age and a statement signed by their parent or guardian consenting to their employment. In the absence of a parent or guardian, a person over 18 years of age with whom the minor resides may sign the consent statement.

Resources and Contact Information

For assistance with Ohio work permits for minors, contact the following resources⁚

- Ohio Department of Commerce⁚ 77 South High Street, 23rd Floor, Columbus, OH 43215-6133. Contact them at (614) 644-2239.

- Ohio Bureau of Wage and Hour⁚ This agency enforces Ohio’s minimum wage and child labor laws. They can provide information on work permit regulations and other employment issues.

Remember, these resources are available to provide guidance and answer any questions you may have about Ohio work permits for minors.

Ohio Department of Commerce

The Ohio Department of Commerce plays a crucial role in regulating work permits for minors. They oversee the Division of Industrial Compliance and Labor, which is responsible for enforcing Ohio’s child labor laws, including work permit requirements. The department provides resources and guidance to employers, schools, and families regarding the issuance and management of work permits. They also investigate potential violations of child labor laws and ensure the safety and well-being of young workers.

Ohio Bureau of Wage and Hour

The Ohio Bureau of Wage and Hour, a division of the Ohio Department of Commerce, is responsible for ensuring that employers comply with state and federal labor laws regarding wages, hours, and working conditions. This includes enforcing regulations related to the employment of minors. The bureau provides information and resources to employers, employees, and families about child labor laws, including work permit requirements. They also investigate complaints of wage theft, child labor violations, and other labor law violations.

Additional Information

For those seeking additional information or resources, the Ohio Department of Commerce’s website provides access to various forms, publications, and guidelines related to work permits. These materials include the official application form, instructions, and a physician’s certificate, which may be required in certain circumstances. Furthermore, the website offers contact information for the Ohio Department of Commerce and the Ohio Bureau of Wage and Hour, enabling individuals to seek clarification or address specific inquiries regarding work permits for minors in Ohio.

Columbus City Schools Work Permit Information

Columbus City Schools students between the ages of 14 and 17 who wish to work during the school year must complete a Work Permit Application. This application requires information from both the student and their employer. Students enrolled in alternative education settings, such as homeschooling or GED programs, should submit their applications to the school district in which they reside. For additional information or guidance, contact the Ohio Department of Commerce, Division of Labor and Worker Safety, at (614) 644-2239.

Work Permit Forms and Publications

The Ohio Department of Commerce provides a variety of forms and publications related to work permits for minors. These resources include applications, instructions, guidelines, and license applications. To access these materials, visit the Division of Industrial Compliance’s website and navigate to the “Applications & Forms” section. Click on the “Form Title” in the first column for detailed information about each form and its purpose. For assistance, contact the Ohio Department of Commerce at 77 South High Street, 23rd Floor, Columbus, OH 43215-6133.

Physician’s Certificate for Minor Work Permit

A physician’s certificate is required for a minor’s work permit application unless the student has already submitted a physical for an organized school activity during the school year. The certificate should be completed by a physician before the minor submits their application. It includes details about the student’s name, date of birth, distinguishing characteristics, sex, and the physician’s approval. The certificate serves as documentation of the minor’s physical health and ability to perform the intended work. The form can be downloaded from the Ohio Department of Commerce website.

Obtaining an Ohio work permit for a minor is a straightforward process that ensures the safety and well-being of young workers; By understanding the eligibility requirements, following the application steps, and adhering to the relevant regulations, minors can successfully secure a work permit and begin their employment journey. The Ohio Department of Commerce provides valuable resources and contact information to assist with any questions or concerns.